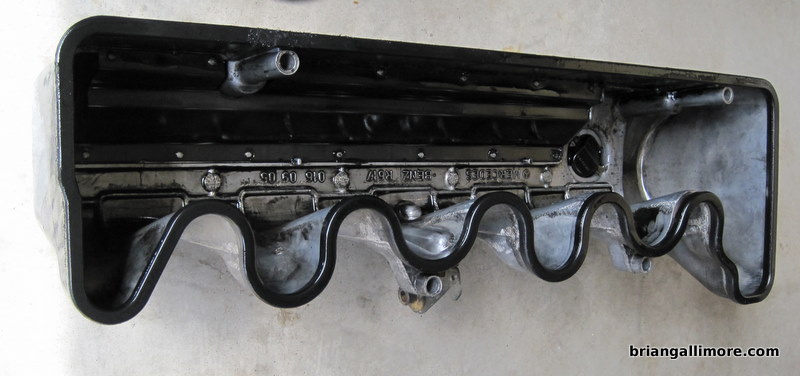

I finally got around to adjusting the valves on Betty. This is something Mercedes says you need to do every 15,000 miles. Every single one of the valves needed adjusting, so I’m sure it has been a while since it was done. I hope the new gasket fixes the leak, because Betty marks her territory everywhere she goes! That big, complicated valve cover only has four bolts to seal it up, no wonder they always leak, seems like they could have done a better job on that one. A found an excellent picture tutorial on the web of the process. I followed the process except for turning the engine by hand. Getting through the 22:1 compression stroke using my arm power doesn’t make sense when you know how to hotwire things to use the starter motor! The most exciting part of the project was making my own wrenches. I bought a few open-end 14mm wrenches from a pawn shop just for the purpose. I used a propane torch to heat them up to make the bends, then welded on a piece of tubing for the handles. The don’t look as good as the $100 units, but they work just fine.

Subscribe to Blog via Email

Recent Comments

- Elaine on Undocumented Secrets of Integrating BACnet MSTP

- Kent Hervey on Interior trailer lights

- Hector Flores on Quadrasteer / Dana 60 Rebuild How-To (ring, pinion, carrier replacement)

- Bill Roberge on Quadrasteer / Dana 60 Rebuild How-To (ring, pinion, carrier replacement)

- Brian Gallimore on Wiring Schematic for Bad Boy ZTE Mower

Top Posts

- Wiring Schematic for Bad Boy ZTE Mower

- The True Political Spectrum

- Quadrasteer / Dana 60 Axle Differences and Similarities

- Troy Bilt Chipper Shredder Review

- Calculating the Volume of Irregular-Shaped Tanks

- Video: Bryson's Bubble Mower

- Economics Made Simple

- Emergency Calling System for Residents of Collin County

- Garden Problem: Tire Potatoes

- Relay Terminal Standard Numbers

Resume

Bookmarks

Archives

Categories

-

Recent Posts

Meta